Materials Test Lab Excellence: Revealing the Tricks of Quality Assurance

Wiki Article

Expert Products Screening Lab: Ensuring Product Efficiency

By subjecting materials to strenuous screening procedures, these labs provide valuable understandings that help suppliers make notified choices. Partnering with a professional materials testing lab provides many advantages, consisting of boosted product top quality, minimized danger of failure, and improved consumer complete satisfaction. In this article, we will discover the importance of materials testing and why it is crucial for making sure item performance (materials test lab).

Relevance of Materials Testing in Item Advancement

Materials testing plays an essential function in guaranteeing the quality and integrity of items throughout the growth procedure. It entails subjecting products to various tests and analyses to review their mechanical, physical, and chemical properties. Because it helps makers determine if the materials made use of in their products satisfy the called for requirements and specs., this testing is important.One of the main reasons that materials screening is essential in item advancement is that it helps identify possible weaknesses or defects in the products. By subjecting them to rigorous testing, producers can examine their strength, resistance, and longevity to deterioration. materials test lab. This info is crucial in creating items that can stand up to the needs of real-world applications and guarantee long-term efficiency

Materials screening also helps in maximizing item style and efficiency. By comprehending the habits of different materials under varying conditions, makers can make enlightened decisions concerning selecting the most appropriate products for particular applications. They can also recognize locations for improvement and make required modifications to boost item performance and reliability.

Moreover, products screening plays an essential function in guaranteeing item safety and security and conformity with regulative standards. By examining materials for toxicity, flammability, and other security criteria, manufacturers can recognize any kind of potential dangers connected with their products. This allows them to take necessary measures to alleviate these risks and make sure the safety of end-users.

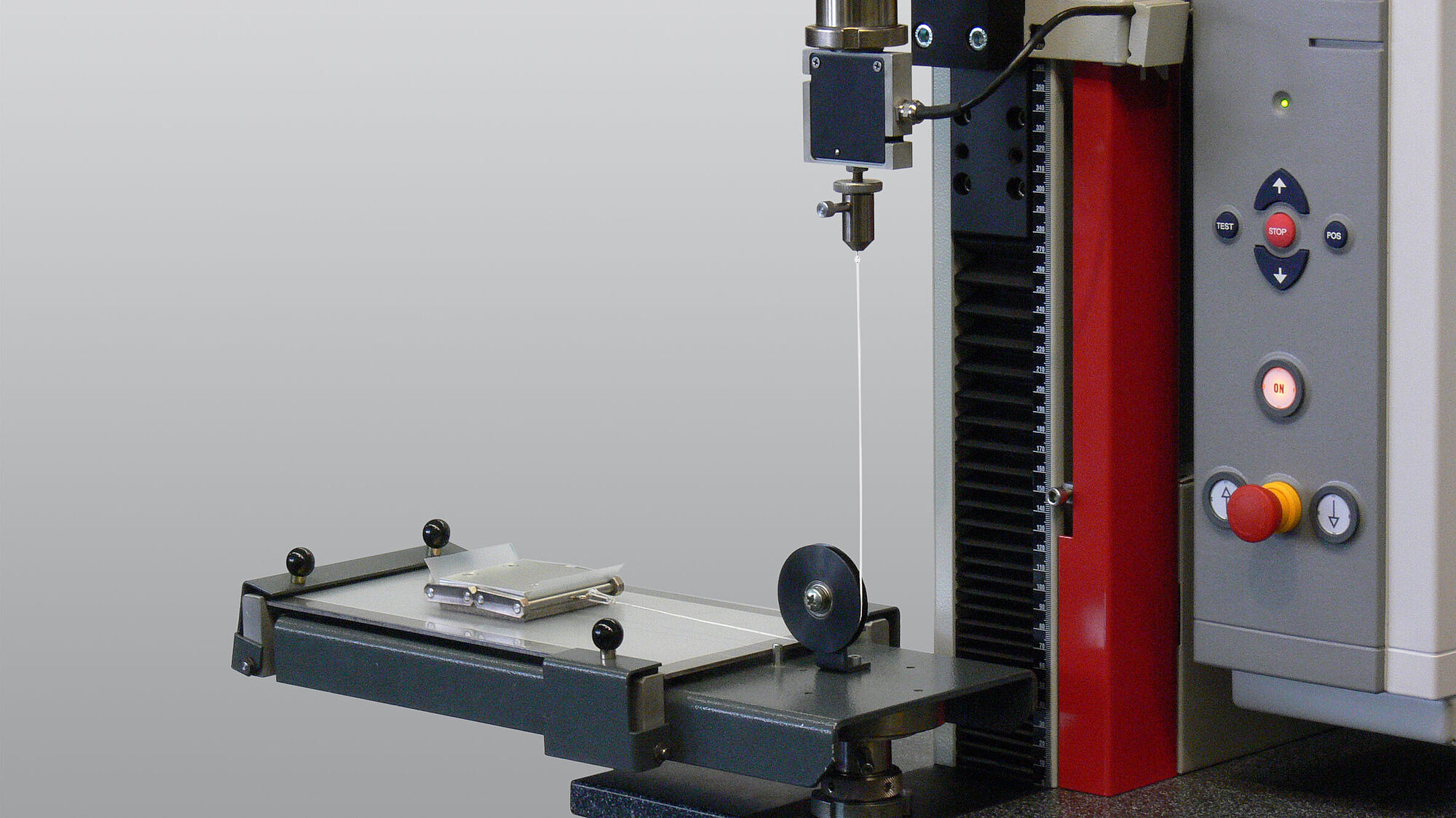

Kinds Of Examinations Performed in a Products Testing Laboratory

A products testing laboratory carries out a wide variety of examinations to examine the residential properties and performance of numerous products made use of in item development. These examinations are essential in making certain that products meet the needed standards and perform as expected in real-world conditions. One typically carried out test is the tensile test, which measures the toughness and ductility of a material by subjecting it to tension until it breaks. Compression tests, on the various other hand, assess a material's capacity to endure compressive forces. Fatigue examinations examine a product's durability by subjecting it to duplicated loading and unloading cycles, mimicing real-life usage conditions. Influence tests measure a material's resistance to extreme and abrupt forces, such as those experienced during an accident. Other examinations include firmness testing, which establishes a material's resistance to imprint or damaging, and thermal testing to evaluate just how materials react to temperature level adjustments. Additionally, corrosion testing reviews a material's resistance to corrosion and destruction in various atmospheres. By performing these tests, materials evaluating labs guarantee that suppliers can count on the efficiency and toughness of their products.Function of Materials Screening in Ensuring Product Quality

One secret aspect in making sure product top quality is the role of products testing. Products screening plays a crucial role in determining the efficiency, dependability, and security of a product. By subjecting materials to numerous tests and analyses, producers can determine any potential problems or weaknesses that can compromise the quality of the last product.Products screening helps in reviewing the physical, mechanical, and chemical properties of products made use of in the production procedure. This consists of testing for residential properties such as tensile toughness, deterioration, hardness, and flexibility resistance. Via these tests, producers can make certain that the products meet the called for specifications and criteria.

By performing strenuous products testing, suppliers can obtain important understandings into the behavior and characteristics of the materials they utilize. This information allows them to make informed choices pertaining to product selection, design enhancements, and high quality control steps.

Ultimately, the function of products screening in making certain item top quality is crucial for producing reliable, resilient, and high-performing items that fulfill customer assumptions and regulative demands. It assists manufacturers to identify and attend to any kind of prospective concerns early in the manufacturing procedure, bring about improved item performance and client complete satisfaction.

Benefits of Partnering With a Specialist Products Testing Lab

Partnering with an experienced materials screening laboratory provides numerous vital benefits in ensuring the performance and high quality of items. By teaming up with a specialized testing lab, businesses can tap into their comprehensive expertise and experience in materials analysis and analysis. One of the major advantages is access to modern testing tools and methods that may not be readily available in-house. These advanced strategies make it possible for the lab to precisely examine the physical, chemical, and mechanical buildings of products, offering useful insights into their performance and durability.One more benefit is the impartial nature of the screening procedure (materials test lab). Professional products evaluating labs operate independently and have no beneficial interest in the result of the examinations. This impartiality guarantees that the results gotten are reputable and unbiased, allowing organizations to make educated decisions based on the data supplied

Furthermore, partnering with an expert lab helps to streamline the screening procedure and decrease time-to-market. These labs have the essential resources and abilities to handle a wide variety of screening requirements effectively and successfully. By contracting out materials testing, companies can concentrate on their core proficiencies and save beneficial time and sources.

Additionally, working together with a skilled materials checking lab can boost a business's online reputation and integrity. By having their products examined and certified by a credible third-party laboratory, organizations can show their dedication to high quality and client fulfillment. This can help construct count on with clients and distinguish their items on the market.

How Materials Testing Contributes to Consumer Complete Satisfaction

Products testing plays a crucial role in ensuring consumer contentment with items. By subjecting materials to rigorous screening, manufacturers can examine their efficiency and quality, guaranteeing that they go beyond or fulfill consumer expectations. This process aids to recognize any type of prospective problems or weak points in the products, permitting producers to make necessary renovations prior to the item YOURURL.com reaches the marketplace.Customer satisfaction is straight affected by the performance and resilience of the products they acquire. Products testing assists makers review the toughness, flexibility, and sturdiness of products, ensuring that products can withstand the designated use and carry out as anticipated with time. By making certain that items are made from high-grade products, suppliers can improve consumer satisfaction by providing products that satisfy their demands and offer resilient efficiency.

In addition to efficiency, materials testing also contributes to consumer security. Checking products for possible hazards, such as poisoning or flammability, assists producers ensure that their products satisfy safety and security requirements and regulations. By offering secure and reputable products, suppliers can develop trust fund with consumers, enhancing their overall satisfaction and commitment.

Conclusion

Finally, products testing plays an important role in item advancement by making certain product efficiency and high quality. By conducting numerous tests in a products testing laboratory, makers can recognize any defects or weak points in their products and make required improvements. Partnering with a skilled products evaluating lab brings many benefits, such as reputable and precise outcomes, knowledge in screening methods, and compliance with industry criteria. Inevitably, products checking contributes to consumer contentment her explanation by delivering premium and trustworthy products to the market.One of the primary reasons why products testing is crucial in product advancement is that it assists determine possible weaknesses or defects in the products. By comprehending the behavior of various products under varying problems, makers can make enlightened decisions regarding choosing the most suitable materials for particular applications.A products screening laboratory performs a wide array of examinations to review the buildings and performance of various materials made use of in item advancement. Various other examinations consist of solidity testing, which identifies a product's resistance to indentation or scratching, and see this website thermal testing to evaluate how products respond to temperature modifications.In conclusion, materials testing plays a critical role in product growth by making certain product efficiency and quality.

Report this wiki page